Photocatalyst 光觸媒

Brought to you by Advance Medical & Health Products

There are a lot of similar products, why should we select your Medical Grade Photocatalyst?

- Unlike other cheaper counterparts, Medical Grade Photocatalyst was developed in Japan and manufactured in Taiwan. It has incorportated nano-technology in the manufacturing process.

- The content of Titanium Dioxide reaches 10% by weight。

- It is active even in visible light, unlike other products necessitate usage of ultraviolet light

- It contains nano sized colloidal silver. Even there is no light, it is still bactericidal (but cannot offer any effect on smell)

- It has independent third party assessment report

7 technological breakthrough of Medical Grade Photocatalyst

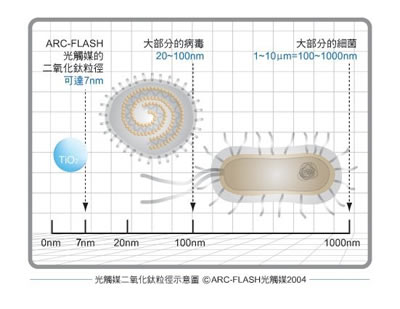

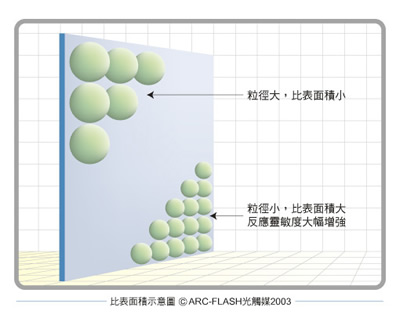

| 1. Size of the titanium oxide granule |

| Medical Grade Photocatalyst has a usual grain size of 4-5nm, with most of them being less than 7nm. With a smaller grain size, the surface to volume ration is much larger, and so as the light penetration rate, its photocatalytic activity will be much higher. |

|

|

| 2. Active with visible light |

| Medical Grade Photocatalyst is active under visible light. Even the activity is less than that under ultraviolet light illumination, with the prolonged exposure of visible light, its effectiveness will exceed the usual requirement. Furthermore, you need not install ultraviolent equipment, save the cost, and avoid being exposed to the hazardous ultraviolet light. |

|

| 3. Content of Titanium dioxide |

| Medical Grade Photocatalyst has its active ingredient being Titanium Dioxide. The content is up to 30% by weight (i.e.1L of the solution contains 300g of Titanium Dioxide, 10 times higher than other "similar" products) |

| 4. Dispersion technology |

| Titanium Dioxide is a suspension in aquatic solvent. With time, being heavier than water, these granules will settle at the bottom and clump together. No matter how small the granules are made into, when clump together, these nano-technology will not work. Our technological breakthrough prevents this from happening. |

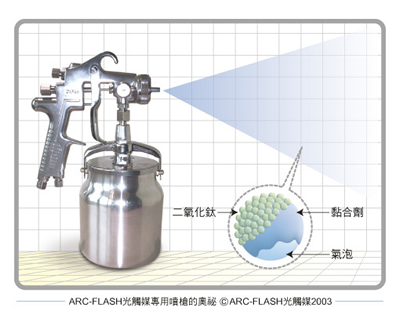

| 5. Direct spray technology |

| Medical Grade Photocatalyst can be sprayed with our specially selected spray gun. The mist is down to 1μm, and the surface tension will place the binder and the Titanium Dioxide granules on the surface and ready to be adhered to the surface of the directed subject. Further than that, there is no need to spray the inorganic primer before the procedure. |

|

| 6. Binder |

| Binder sticks the photocatalyst granules to the surface. Usual binders are organic in nature. The binder of Medical Grade Photocatalyst, however, can withstand the photocatalytic reaction. |

| 7. Dry quickly |

| Medical Grade Photocatalyst when sprayed on rough surface (wall and wood), will dry in few seconds. 30 seconds are all it needs to dry on smooth surfaces such as tile and marble. Quick dry allows the site be used immediately after the treatment. It harden with time and reach the maximal hardness (4H) in just 2 weeks. 4H hardness is stronger than paint on your car. As you will expect, it will stand the test of time unless someone deliberately tries to rub it off (He deserves that as he will need a lot of strength and stamina to do so) |

"Cost speaks for the quality!